professional enterprise engaged in the wholesale of forklift parts

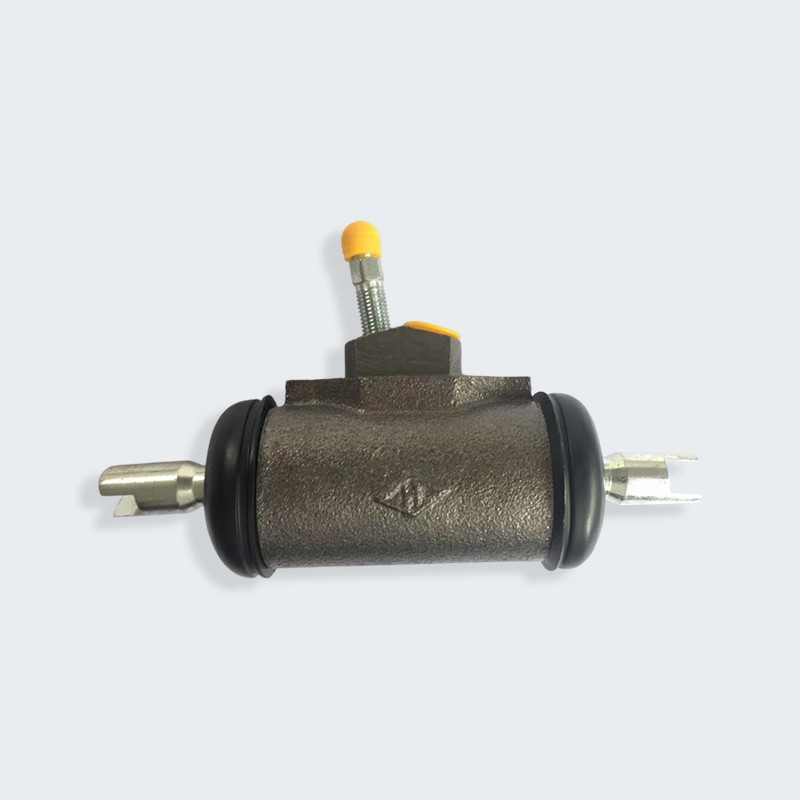

Hangcha forklift R15/A15 Heli forklift 1.5 ton brake cylinder

Hangcha forklift R20/A20/J20 Heli forklift 2 ton left brake cylinder

Hangcha forklift R20/A20/J20 Heli forklift 2 ton right brake cylinder

Heli 2 ton (new pattern) TCM 2-2.5 ton / FD forklift brake cylinder

Hangcha R45/Heli 4.5 ton/TCM 4.5 ton forklift brake cylinder (using brake oil)

Hangcha R45/Heli 4.5 ton/TCM 4.5 ton forklift brake cylinder (using hydraulic oil)

Hangcha forklift/Heli forklift 4.5 ton (widened) brake cylinder

Hangcha/Heli/TCM forklift 5-7 ton brake cylinder (using brake oil)

Hangcha/Heli/TCM forklift 5-7 ton brake cylinder (using hydraulic oil)

Lonking forklift 5-7 ton LG50 Heli 5-7 ton (Widened) forklift brake cylinder

Hangcha 75HS (power braking) Hangcha / Heli 8-10 ton (single pump) forklift brake cylinder

Enterprise establishment

Employees

Zhuji Prebo Brake System Technology Co., Ltd., established in 2009, independently develops and produces a wide range of brakes, brake shoes, flexible shafts, hoses, high-pressure hoses, copper pipes, piston rods, springs, screws, wire harnesses, and other products. Our forklift brakes and forklift rims are suitable for a wide range of brake applications.

Forklift brakes - guardians of precise control and safe parking

Brakes, commonly known as braking systems, are the cornerstone of forklift safety performance. It can control deceleration, achieve parking and stabilize parking on slopes. In a crowded working environment, whether a forklift loaded with goods can be braked accurately and promptly is directly related to the safety of operators, goods and surrounding facilities.

Forklift brakes have continuously evolved and have shown the following outstanding advantages:

High reliability and stability: Both disc brakes and drum brakes use special materials that are resistant to high temperatures and wear (such as ceramic brake pads and high-phosphorus cast iron brake drums) to ensure stable performance and strong resistance to thermal decay under frequent starts and stops and high-intensity operations.

Sensitive responsiveness: Thanks to the popularization of hydraulic or pneumatic assist, modern forklift brake pedals have small force and quick response, achieving precise control that is "effective as soon as you step on it" and greatly shorten the braking distance.

Maintenance-free and long life: Many new forklifts feature enclosed wet brakes. This design seals the brake assembly in a transaxle filled with cooling oil. It has the remarkable characteristics of good heat dissipation, low wear and almost no maintenance. It is especially suitable for harsh working conditions with moisture and dust, and has an extremely long service life.

Integrated safety functions: The braking system is often linked with the hill start assist function to prevent the car from rolling when changing direction on a slope. At the same time, the multiple guarantees of the service brake and parking brake (handbrake) provide "double insurance" for safety.

Forklift steel rims - load-bearing and driving

The steel ring, also known as the rim, is the component that connects the tire to the axle. It is not only the "feet" of the forklift, but also undertakes the following core tasks:

Heavy duty bearing: directly bear the weight of the forklift, cargo weight and dynamic impact load.

Power transmission: transmits the torque of the drive motor to the tires to generate driving force.

Support carcass: Provide rigid support for pneumatic tires to maintain their standard shape and air pressure.

Advantages and features

Structural strength: It is made of high-strength steel that is integrally stamped or precision welded. It has a solid structure, can withstand huge radial (load-bearing) and axial (steering) loads, and has strong impact resistance and deformation resistance.

Precise dynamic balance: The excellent manufacturing process ensures that the steel ring itself has minimal runout and excellent dynamic balance, which is crucial to ensure the smooth driving of the forklift, reduce abnormal tire wear, and protect the drive axle and steering system.

Excellent heat dissipation performance: The design of the steel rim takes full consideration of heat dissipation needs and helps solid tires or brake systems dissipate a large amount of heat generated during operation through reasonable spoke shapes and ventilation holes.

Wide applicability and economy: The steel ring material is strong and durable, highly adaptable to the environment, and corrosion-resistant treatment (such as plastic spraying) can cope with humid and corrosive environments. It has a long service life and low overall cost.