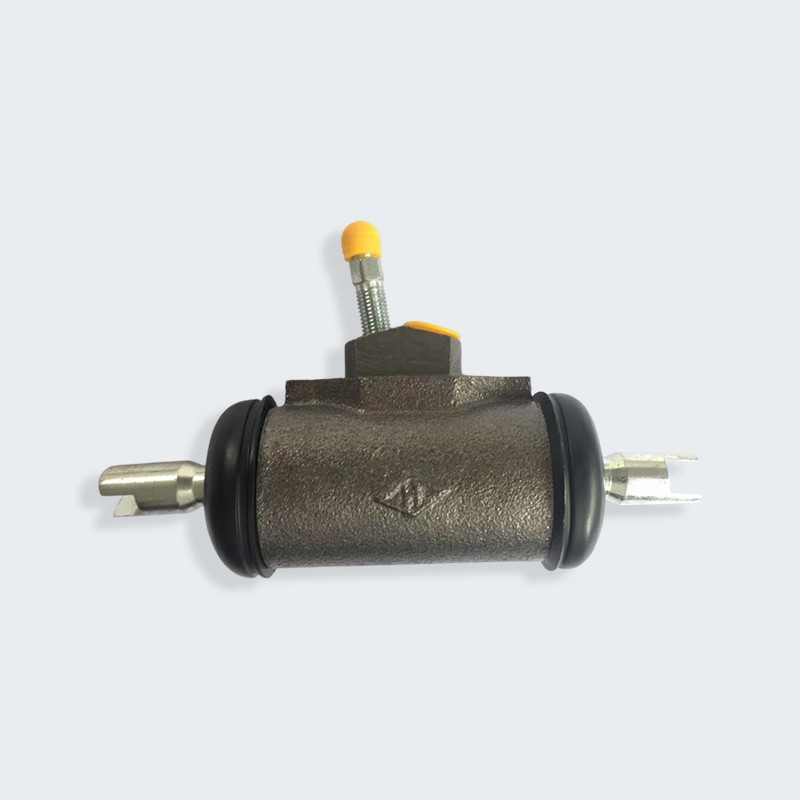

The right brake wheel cylinder of Hangcha R20/A20/J20 series and Heli 2-ton forklifts adopts hydraulic drive and automatic adjustment mechanism, which accurately converts oil pressure into mechanical force of brake shoe through double-acting piston structure, so as to achieve close fit between brake drum and brake shoe. The brake system design follows the principle of ergonomics, and integrates the collaborative working mechanism of hydraulic brake master cylinder and slave cylinder to ensure rapid braking response and balanced distribution of braking force. Hangcha products effectively reduce braking noise and extend component life by optimizing brake shoe friction coefficient and dynamic adjustment technology of brake clearance; Heli forklift adopts vacuum booster enhanced braking system, which can maintain stable braking performance under heavy load or slope conditions. Both are equipped with double safety protection: the brake fluid leakage protection device can monitor abnormal oil pressure in real time, while the emergency power-off switch and electronic hydraulic overload protection module form a double braking safety net, which meets international safety certification standards.

Hangcha R20/A20/J20 series brake wheel cylinders are customized to suit the characteristics of different vehicle models: the R20 series uses a lightweight aluminum alloy cylinder design to meet the low energy consumption requirements of electric forklifts; the A20 series has a reinforced sealing structure to withstand the corrosive environment of battery electrolytes; the J20 internal combustion tractor is equipped with high-temperature resistant brake pads to adapt to the high thermal load conditions of diesel engines. The Heli 2-ton forklift brake wheel cylinder is designed to be quickly disassembled and assembled through a modular design, and its non-contact proximity switch and waterproof connectors significantly improve the reliability of the electrical system. In terms of maintenance, Hangcha products use a fully open hood and a tool-free disassembly base plate design, and no lifting equipment is required for brake wheel cylinder inspection; the Heli forklift is equipped with a visual fault diagnosis system, which displays the brake system status in real time through an LED instrument, and combined with a side-movable battery design, greatly shortens the brake system maintenance downtime. Both are CE certified, and the core components are from international brand suppliers to ensure the long-term stability of the braking performance.

English

English عربى

عربى