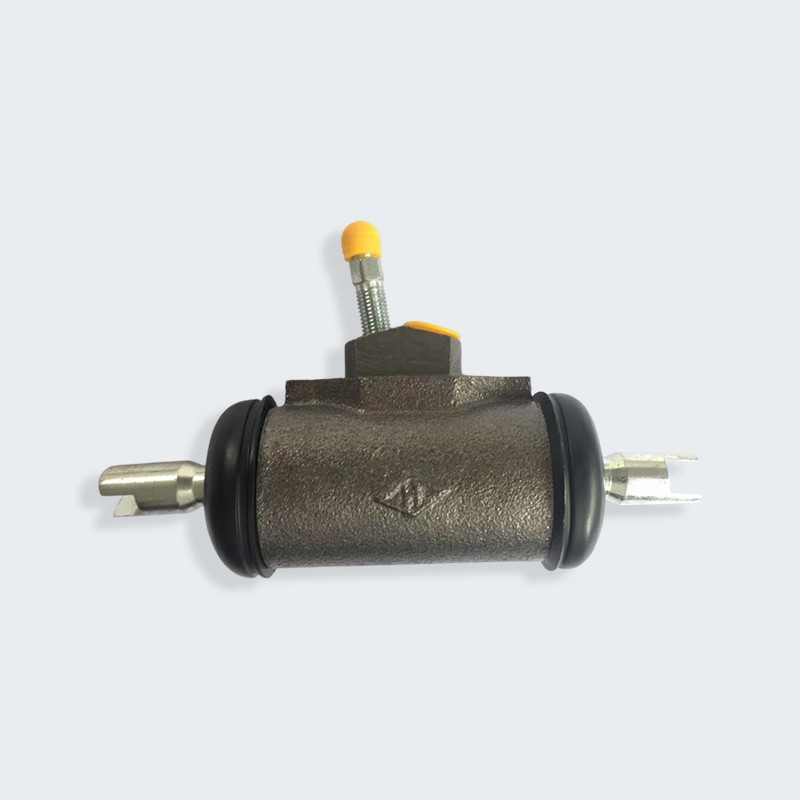

HangchaR20, A20 and J20 series forklifts are core products designed by Hangcha Group for different working conditions. The left brake wheel cylinder is a key component to ensure the stable operation of the forklift's braking system. The brake wheel cylinder is cast with high-strength alloy materials. After precision machining and surface treatment, it has corrosion resistance and wear resistance, and can adapt to high-intensity working environments. The internal piston assembly adopts a double-seal structure design, with imported sealing rings, which effectively prevents hydraulic oil leakage and ensures the accuracy and durability of brake pressure transmission. In addition, Hangcha's brake wheel cylinder is deeply adapted to the vehicle's braking system. By optimizing the hydraulic circuit design, the rapidity and stability of the brake response are achieved, which significantly improves the operational safety and reliability of the forklift in complex warehousing or logistics scenarios.

The left brake wheel cylinder of Heli 2-ton forklift is designed for counterbalanced forklifts. Its core advantage lies in modular structure and high compatibility. The component adopts a lightweight aluminum alloy cylinder body, which reduces the vehicle's dead weight while ensuring structural strength and improving energy efficiency. The integrated pressure compensation valve inside the brake wheel cylinder can automatically balance the hydraulic fluctuations caused by temperature changes during braking, avoiding soft or dragging brakes. In addition, Heli brake wheel cylinders are manufactured in strict accordance with international safety standards, key seals are made of German brands, and their durability has been rigorously tested and verified. Its installation interface adopts a standardized design, which can be quickly adapted to a variety of Heli 2-ton forklift models, reducing user maintenance costs and downtime. It is an ideal choice for logistics, manufacturing and other fields that pursue efficiency and safety.

English

English عربى

عربى