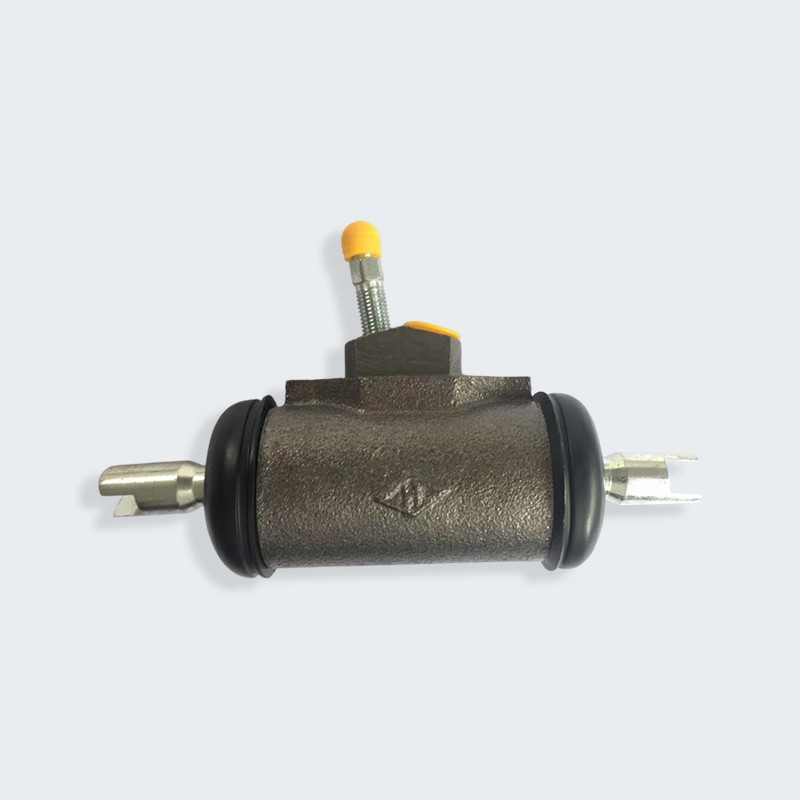

As the key actuator of the forklift braking system, the brake wheel cylinder accurately converts the hydraulic pressure transmitted by the master cylinder into mechanical thrust, drives the brake shoe to fit closely with the brake drum, and achieves a smooth and reliable braking effect. The brake wheel cylinders equipped on HangchaR30 and Heli 3-ton series forklifts are cast with high-strength alloy materials, have excellent fatigue resistance and corrosion resistance, and can adapt to the frequent start-stop requirements in high-intensity working environments. Its internal piston components adopt precision grinding technology to ensure hydraulic sealing and action sensitivity, effectively reduce braking delay, and improve operational safety. The component realizes rapid disassembly and maintenance through modular design, reduces equipment downtime, and is compatible with brake shoes of various specifications to meet the adaptation needs of different working conditions.

As leading brands in the domestic forklift field, Hangcha and Heli strictly follow international safety standards in the research and development of braking systems. Their brake wheel cylinder products have passed multiple pressure tests and durability verifications to ensure stable performance under extreme working conditions. This component is widely used in logistics warehousing, port loading and unloading, manufacturing material handling and other scenarios. It is deeply matched with the hydraulic brake system of Hangcha R30 and Heli 3-ton series forklifts, and can effectively solve common problems such as soft braking and delayed response. In addition, the brand officially provides original parts warranty service, cooperates with the national joint warranty network, and provides users with full-cycle support from selection guidance to after-sales maintenance, helping enterprises reduce the cost of equipment management throughout the life cycle.

English

English عربى

عربى