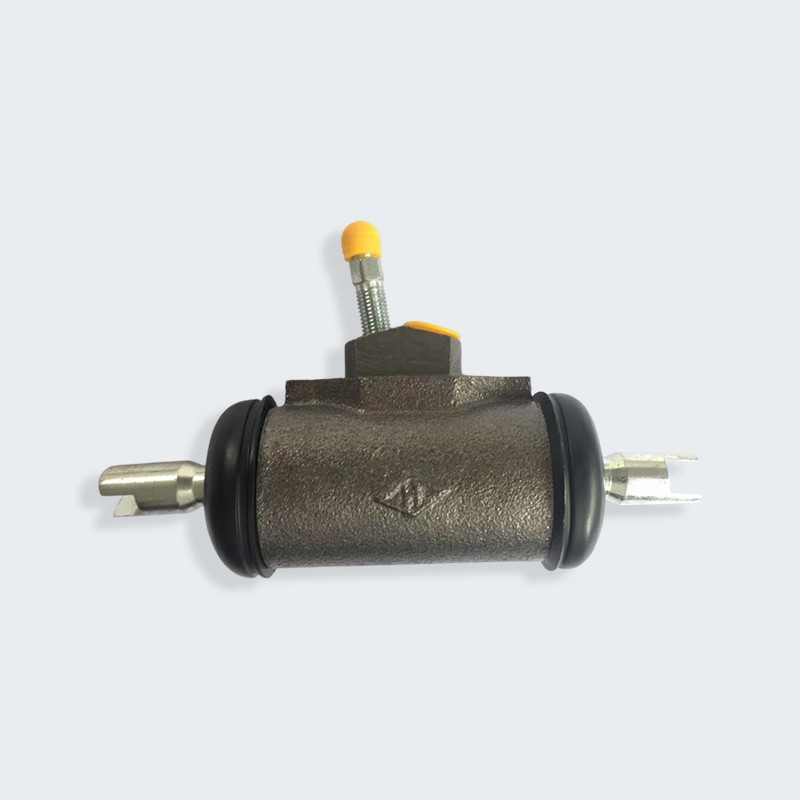

This brake shoe is specially adapted for 2-ton forklifts of mainstream brands such as Hangcha, Heli, Toyota, etc. It is the core consumable to ensure the braking safety and control response of small and medium-sized forklifts. Its composite friction lining is optimized for warehouse turnover, indoor operations and ramp braking scenarios, providing linear and progressive braking force output to ensure that the vehicle maintains stable deceleration and precise parking when switching between no-load and full-load. By effectively suppressing brake thermal decay and abnormal wear, it directly maintains the stability of cargo handling, the reliability of equipment operation throughout the life cycle, and the continuity of high-frequency operations, becoming a universal guarantee for the efficient and low-consumption operation of multi-brand small and medium-tonnage forklifts.

The shoe adopts high-temperature sintering process and anti-squealing design, and is compatible with various drum brake systems. The layered gradient friction material ensures low dust emission and long-term friction coefficient stability, and adapts to complex working conditions with high humidity and high dust. The standardized interface enables fast replacement and significantly reduces the maintenance time cost. Its balanced and durable performance not only affects the safety and controllability of each braking, but also enables the standardized management of multi-brand forklift clusters, the efficient coordination of logistics rhythm, and the security foundation support for the green and intelligent warehousing ecology, laying the key operating fulcrum for the intensive operation and maintenance of small and medium-tonnage handling equipment.

English

English عربى

عربى