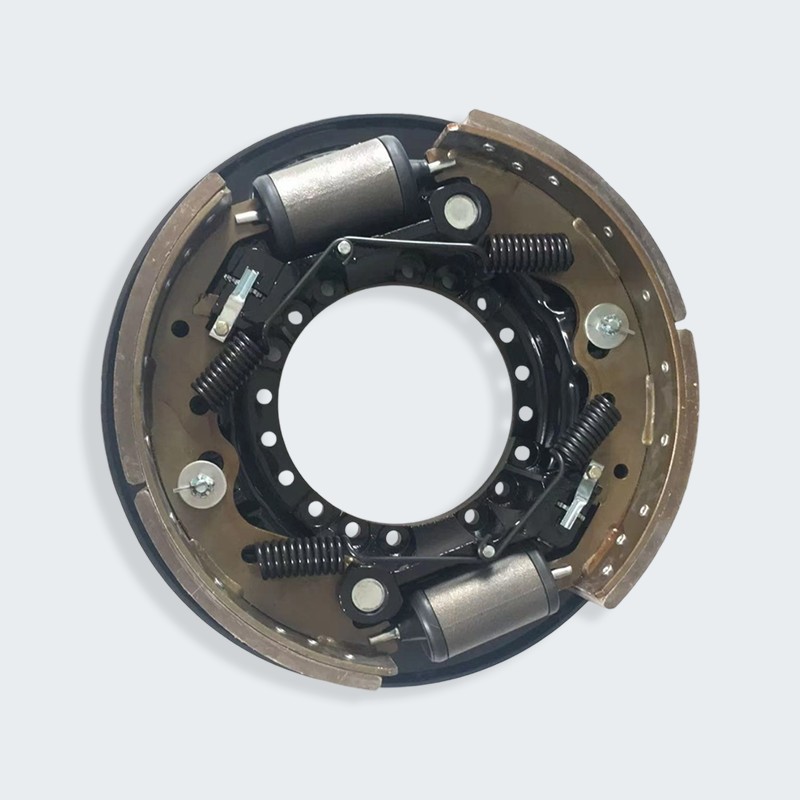

As the core component of Heli forklift's braking system, the 3.8-ton right brake shoe integrates the brand's technical accumulation in the fields of materials science and precision manufacturing. Its main body is cast with high-strength wear-resistant alloy, and the surface is covered with a composite friction material layer. The precision molding process ensures the fit accuracy with the inner wall of the brake drum, and can still maintain a stable braking force output under frequent braking conditions. The product design fully considers the high-load characteristics of forklift operations. By optimizing the horseshoe structure and friction coefficient distribution, the thermal stress generated during braking is effectively dispersed, significantly extending the service life.

This brake shoe is widely suitable for Heli 3.8-ton forklifts, especially for high-intensity operating environments such as logistics warehousing and port terminals. Its modular design supports rapid replacement and reduces downtime maintenance time. Combined with the overall coordinated optimization of Heli's braking system, it can achieve the dual effects of sensitive response and smooth braking. As a standardized accessory of Heli's global supply chain system, the product strictly follows the ISO-certified quality control process, and undergoes multi-dimensional testing from raw material screening to factory testing, providing reliable protection for the safe operation of forklifts. Whether it is daily cargo handling or emergency braking under complex working conditions, this brake shoe can help improve work efficiency and operational safety with its stable performance.

English

English عربى

عربى